PUMPMASTERS LTD

PUMPMASTERS LTDUNIT 14A NASMYTH COURT HOUSTON INDUSTRIAL ESTATE LIVINGSTON, WEST LOTHIAN EH54 5EG, SCOTLAND, UK Tel: 01506 668740 Fax: 01506 668741 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

NITRATE REDUCTION SYSTEMS The presence of Nitrates in water causes many problems, ranging from blue baby syndrome (if fed to babies under six months old) to contamination of poultry if used as feed water for farmed birds. The source of Nitrate in ground water is usually from farming fertilisers. The EEC permitted maximum is 50mg/1 with an advisory maximum of 25mg/1.

Nitrate dissolved in water is not able to be removed by simple filtration. It can only be reduced by either regenerable or disposable cartridge type ion exchange systems or eliminated by Reverse Osmosis (RO). RO systems can be used to treat all of the water for a specific application, or to just remove the Nitrates from a drinking water supply in the kitchen.

For single dwellings with one drinking water tap and low water consumption, a point of use system provides efficient reduction at low cost. For large or multiple properties, commercial and industrial applications, regenerable ion exchange systems will be preferred. It is these systems that are illustrated on this page.

How do Nitrate Removal Systems Work Ion exchange Nitrate removal is a similar process to water softening, using a slightly different polymer resin. The resin removes the Nitrate (and Sulphate due to its chemical similarity) from the water and replaces them with Chloride ions. Once the resin bed is merely exhausted of Chloride ions, the control valve carries out a regeneration of the bed. This is achieved by passing a Chloride rich brine solution (made up of common salt dissolved in water) through the resin bed, which flushes out the Nitrate and Sulphate to drain, replacing them with Chlorides again. The only input required by the user is to ensure that the brine tank is kept topped up with salt. For fixed or consistent flow rates a simple timer controlled valve will suffice. This will effect regeneration of the resin bed at a pre-set time interval. For varying demands a water meter controlled unit is more suitable, regenerating only after a set volume of water has been passed through the resin bed. With applications that require continuous high flows a duty standby "duplex" system will be required.

System Management The choice of valve is entirely dependent upon the application, water use rate and severity of Nitrate contamination. Your water treatment specialist will be able to advise on the best option for your particular problem. Top of the range microprocessor controlled units use very little salt, are able to cope easily with varying demand and remove 90 to 93% of the Nitrates present in the water. Simpler, lower specification valves remove between 80 and 85% of the Nitrate present, can be purchased in either metered or timelock control and are normally suited to most domestic applications with a Nitrate level not in excess of 100mg/1.

System Management and Regeneration Regeneration is controlled by a valve mounted on top of the pressure vessel containing the resin. A solution of brine is drawn through the column and the Chloride from the salt displaces the Nitrate and Sulphate ions flushing them down the drain. The regeneration process can be initiated by a time clock or by a meter which regenerates the resin after a pre-set volume of water has been treated.

Specifying and Sizing The capacity of a Nitrate removal unit is a function of the amount of resin in the column, the amount of Nitrate and Sulphate, and the amount of salt used at each regeneration. The output will therefore increase or decrease according to local circumstances and the salt dosage rate. The raw water can also change dramatically in composition depending on the season and weather conditions, so your water treatment specialist will take potential variations into account when fitting and programming your Nitrate Removal Unit.

Technical Details and Part Numbers

Domestic/flow systems are usually assembled into a cabinet which also acts as a brine tank.

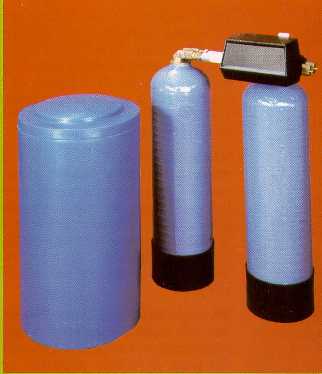

Commercial and industrial Nitrate Removal Units are built with separate brine tanks, and can be Simplex systems (single resin column) or duty standby Duplex systems (twin resin columns). The systems will be assembled with the most suitable valve for your peak flow rate. Your installer will advise you of the most suitable system for your needs.

Commercial System Data

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||